Data Inaccuracies in Arc Flash Analysis

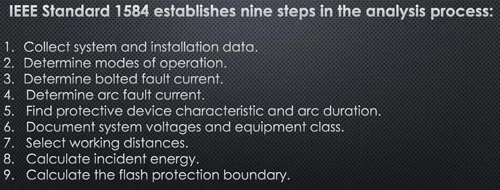

Arc flash hazard analysis serves as a vital risk assessment tool, guiding decisions on protective equipment, safety protocols, and system design. However, the reliability of this analysis hinges on the accuracy and completeness of the underlying electrical system data. Outdated information, missing documentation, and erroneous assumptions corrupt calculations, resulting in misleading safety recommendations.

Arc flash hazard analysis is essential for ensuring the safety of personnel working with or around electrical systems. This process relies heavily on accurate data regarding electrical system components, configurations, and operating conditions. However, challenges arise when the data is inaccurate or incomplete.

Visit Our Arc Flash Study Course

Sources of Data Inaccuracies

- Outdated System Documentation: Electrical systems evolve over time. Often, modifications and upgrades are not fully reflected in schematics, one-line diagrams, and equipment specifications. Relying on outdated documents introduces a cascade of errors into the hazard analysis.

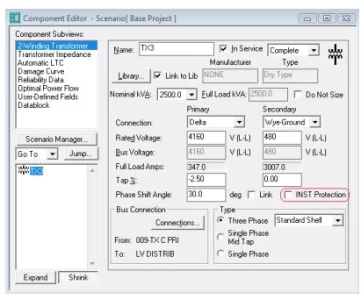

- Missing Equipment Information: Incomplete manufacturer data on components like fuses, circuit breakers, or transformers creates gaps during modeling. Analysts may be forced to make assumptions or use generic values, sacrificing accuracy.

- Incorrect Conductor Specifications: Overlooked cable sizing, material differences, or underestimating conduit lengths can significantly underestimate the resistance in a circuit, leading to lower calculated fault currents.

- Human Error: Data entry mistakes, misinterpretation of specifications, or incorrect assumptions during the analysis process are additional potential sources of error.

Consequences of Incorrect Data

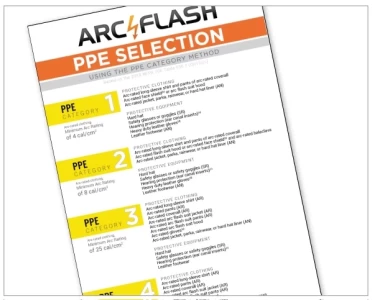

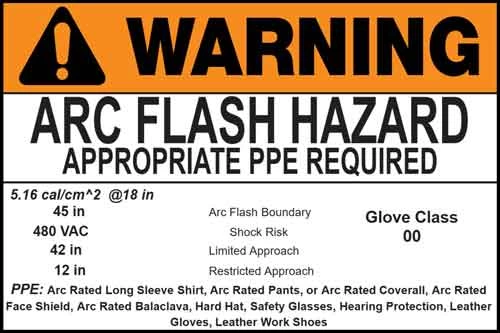

- Underestimation of Incident Energy: If inaccuracies lead to lower calculated fault currents or faster protective device clearing times, the estimated incident energy at a given location may be too low. This puts workers at risk, as the selected PPE or established arc flash boundaries could be insufficient.

- Overestimation of Hazard: Conversely, incorrect data can make the hazard appear worse than reality. This can lead to unnecessary investments in arc-resistant equipment, excessive safety restrictions hindering work efficiency, or overly conservative PPE categories.

- Non-Optimized Risk Mitigation: Faulty analyses prevent organizations from targeting resources where they have the most potential for safety impact. The misalignment of risk perception and actual risk leaves vulnerabilities unaddressed.

Ramifications of Improper Risk Calculations

The consequences of incorrect arc flash hazard analysis are significant, impacting both safety and compliance.

Safety Risks

The primary concern of inaccurate arc flash analysis is the safety risk to personnel. Underestimating the arc flash hazards can lead to the use of inappropriate PPE and safety protocols, exposing workers to severe injuries or fatalities in the event of an arc flash incident.

Compliance Issues

From a regulatory perspective, incorrect analyses can result in non-compliance with safety standards like NFPA 70E and OSHA regulations. This non-compliance can lead to legal and financial repercussions, including fines, increased insurance costs, and potential litigation.

Technical Considerations for Accurate Analysis

Ensuring the accuracy of data used in arc flash hazard analysis is a technical challenge that requires a meticulous approach.

System Review and Verification

A thorough review and verification of system information are imperative. This includes validating the specifications of all electrical components and ensuring that system modifications are accurately reflected in the documentation.

Dynamic System Analysis

Electrical systems are dynamic, with changes occurring due to upgrades, expansions, and maintenance activities. Continuous monitoring and updating of the system data are necessary to maintain the accuracy of the arc flash hazard analysis.

Advantages of Accurate Data Analysis

While the challenges are significant, the benefits of accurate arc flash hazard analysis are substantial.

Enhanced Safety

Accurate analysis leads to better-informed decisions regarding safety measures and PPE, significantly reducing the risk of injury from arc flash incidents.

Regulatory Compliance

Accurate data and analysis ensure compliance with safety regulations, avoiding the financial and reputational costs associated with non-compliance.

Operational Efficiency

An accurate understanding of the arc flash hazards can improve the efficiency of maintenance and repair activities, minimizing downtime and increasing the reliability of the electrical system.

Conclusion

Data inaccuracies in arc flash hazard analysis present significant challenges to safety and compliance. Accurate equipment specifications, complete documentation, and proper risk calculations are essential for protecting personnel from the dangers of arc flash incidents. By prioritizing data accuracy and adhering to industry standards, organizations can mitigate the risks associated with arc flash hazards and ensure a safer working environment.

Arc flash hazard analysis is a powerful tool for safeguarding electrical workers. However, its effectiveness rests on recognizing the vulnerability of the process to inaccurate data. By proactively combating data errors and cultivating a culture of accurate documentation, organizations can ensure their arc flash risk assessments genuinely contribute to a safer workplace.