The Impact of Incorrect PPE Usage

Personal Protective Equipment (PPE) is a critical line of defense in protecting workers from the dangers of arc flash incidents. These incidents, characterized by intense bursts of energy caused by an electrical fault, can result in severe injury or death. Therefore, using the correct PPE, properly sized and worn, is essential for ensuring safety in environments where arc flash risks exist.

Visit Our Arc Flash Study Course

The Risks of Inappropriate PPE

Using incorrect PPE can lead to a false sense of security and increased vulnerability to arc flash hazards.

Mismatched Protection Levels

PPE for arc flash is rated based on the level of protection it provides against thermal energy. Wearing PPE that does not meet the minimum required protection level for the specific arc flash hazard can result in catastrophic injuries. The energy from an arc flash can easily penetrate insufficient PPE, causing burns or more severe injuries.

Consequences of Poor Fit

Incorrectly sized PPE not only compromises comfort but also safety. PPE that is too large can catch on equipment or not provide the intended coverage, while too small PPE can restrict movement and lead to exposure of body parts to arc flash hazards. Proper fit is essential to ensure full protection coverage and allow the wearer to perform tasks without hindrance.

Technical Considerations in PPE Selection

Selecting the right PPE involves understanding the specific hazards of the workplace and the nature of the electrical work being performed.

Understanding Arc Flash Ratings

PPE is categorized based on arc flash protection levels, typically measured in calories per square centimeter (cal/cm²). These ratings indicate the gear's capability to protect against specific levels of incident energy. Workers need to be equipped with PPE that matches or exceeds the calculated incident energy levels of their work environment.

Regular Assessment and Training

Continuous risk assessment and training are vital to ensure that workers understand the importance of using correctly rated and fitting PPE. Regular training sessions can help reinforce the correct use and maintenance of PPE, as well as updates in arc flash safety standards and technology.

The Role of Compliance and Standardization

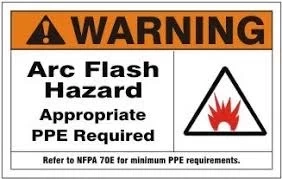

Compliance with safety standards such as NFPA 70E and OSHA regulations is crucial in managing arc flash risks effectively.

Adherence to Safety Standards

These standards provide guidelines for the proper selection, use, and maintenance of arc flash PPE. Adherence to these guidelines ensures that workers are adequately protected based on the latest safety research and best practices.

Standardization and Quality Assurance

Implementing standardization in PPE procurement and usage ensures consistency in protection levels. Quality assurance processes are critical to verify that PPE meets the necessary safety standards and performance specifications.

The Benefits of Proper PPE Usage

Using the correct PPE in the right manner significantly reduces the risk of injury in the event of an arc flash.

Enhanced Worker Safety

Properly selected and used PPE can mean the difference between minor injuries and life-threatening conditions. Ensuring that workers have and use the correct PPE can dramatically reduce the severity of injuries from arc flash incidents.

Increased Operational Efficiency

When workers feel safe and are properly protected, they can perform their tasks more efficiently and with greater confidence. This not only enhances productivity but also contributes to a positive safety culture within the organization.

Conclusion

The correct use of PPE is paramount in protecting against arc flash hazards. The consequences of using inappropriate or incorrectly sized PPE can be severe, leading to increased risk of injury or fatality. By adhering to safety standards, conducting regular training, and ensuring proper selection and use of PPE, organizations can significantly enhance the safety and well-being of their employees in high-risk electrical environments.