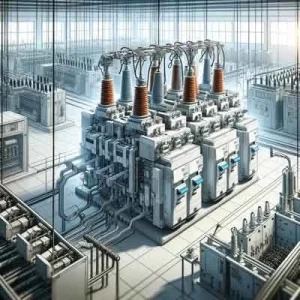

Construction of an Air Circuit Breaker

The construction of an Air Circuit Breaker (ACB) showcases an intricate design aimed at enhancing the safety and efficiency of electrical systems. ACBs are pivotal in preventing equipment damage and ensuring operational continuity by interrupting excessive currents and faults. This expanded article delves deeper into the components and mechanisms that constitute the ACB, illustrating the sophistication behind its functionality.

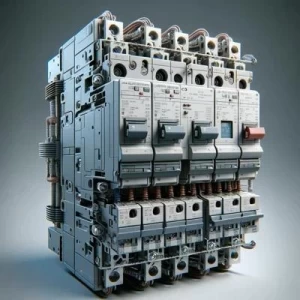

Main and Auxiliary Contacts: The Core of Current Interruption

The ACB features two primary types of contacts: main and auxiliary. The main contacts are crafted from copper, chosen for its superior electrical conductivity, which facilitates the smooth flow of current under normal conditions. These contacts are robust, designed to handle the full load current without significant wear under regular operation. Conversely, the auxiliary or arcing contacts, made from a durable copper alloy, are specially formulated to withstand the extreme conditions of arcing. These contacts come into play during the circuit breaker's operation, taking over the current from the main contacts to prevent their erosion by the intense heat and metal vapor generated by the arc. This dual-contact system is critical for the ACB's longevity and reliability, ensuring that it can perform its protective role without frequent maintenance.

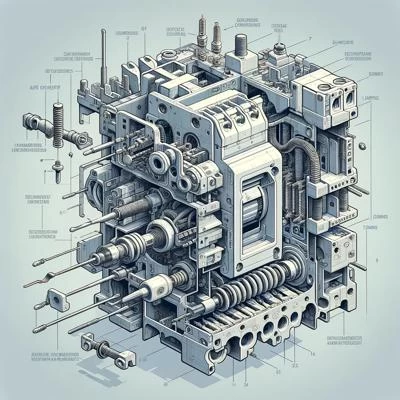

Arc Chute: The Arc Extinguishing Chamber

An arc chute is a vital component of the ACB, designed with refractory materials capable of withstanding and quenching the high-temperature electrical arc. The internal geometry of the arc chute is particularly noteworthy; its walls are contoured to elongate the arc path and force it into close proximity within a confined space. This structure enhances the cooling and quenching of the arc by splitting it into smaller sections, thereby dissipating its energy more efficiently. The effectiveness of the arc chute is crucial for the ACB's ability to interrupt high current flows swiftly and safely, protecting the electrical circuit from damage.

Trip Unit: The Intelligence Behind Fault Detection

The trip unit stands as the ACB's sentinel, continually monitoring the electrical circuit for anomalies such as overloads, short circuits, and faults. It comprises a sophisticated array of protective relays and sensors that assess current and voltage levels, ensuring round-the-clock vigilance. Upon detecting irregularities, the trip unit activates the ACB's opening mechanism, disconnecting the affected circuit from the power source. This rapid response is essential for mitigating potential hazards, highlighting the trip unit's role in the proactive management of electrical safety.

Closing and Opening Mechanism: Ensuring Reliable Operation

The closing and opening mechanism of the ACB is engineered for precision and durability. It incorporates springs, solenoids, and mechanical linkages that facilitate the smooth and reliable operation of the contacts. This mechanism is adept at executing the commands issued by the trip unit, enabling the ACB to respond promptly to detected faults. Moreover, it allows for manual control, providing operators with the flexibility to manage the ACB's status according to the needs of the electrical system. The meticulous design of this mechanism ensures that the ACB can maintain its protective functions over time, even under the rigors of frequent operation.

The construction of an Air Circuit Breaker reflects a harmonious blend of mechanical robustness and electrical sophistication. Each component, from the copper and alloy contacts to the arc chute and the intelligent trip unit, plays a pivotal role in the ACB's operation. The closing and opening mechanism further underscores the ACB's reliability, ensuring seamless integration into electrical systems. Understanding these elements and their interplay is crucial for professionals tasked with the maintenance and management of ACBs, as it provides insights into their operational efficacy and safety contributions. Through meticulous design and engineering, ACBs serve as guardians of electrical systems, offering protection against the potentially devastating effects of uncontrolled current flows.