What is an Air Circuit Breaker?

Air Circuit Breakers (ACBs) are vital components in the electrical systems of commercial, industrial, and utility applications, ensuring the protection and efficient operation of electrical circuits. ACBs operate at atmospheric pressure in air and are designed to interrupt circuit flow to prevent damage from overcurrents, short circuits, or electrical faults. This article delves into the essential aspects of ACBs, highlighting key concepts such as arc chute, arcing contacts, magnetic blowout type, air blast circuit breaker, maintenance and testing, auxiliary contacts, documentation and SOPs, electrical safety, voltage and current ratings, and their applications.

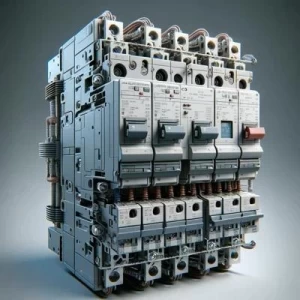

Arc Chute and Arcing Contacts

The arc chute is a critical component of the ACB, designed to extinguish electrical arcs by dividing them into smaller arcs with higher voltages than the system, aiding in their quick extinction. Arcing contacts, often made from a silver and zinc alloy, are engineered to draw the arc across themselves, protecting the main contacts from damage and ensuring the longevity of the breaker. This system is pivotal in maintaining the efficiency and safety of the ACB during operation.

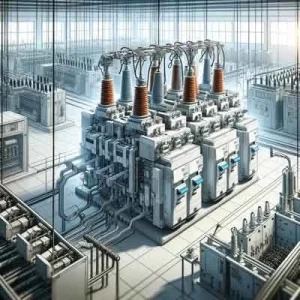

Magnetic Blowout Type and Air Blast Circuit Breaker

Magnetic blowout ACBs utilize a magnetic field, generated by blowout coils, to control and extinguish the arc. This technology is particularly effective in systems up to 11KV, where precise control over the arc is essential. On the other hand, air blast circuit breakers are suited for high-voltage applications (245 KV and above), employing high-pressure air to cool and extinguish the arc quickly. This type is valued for its rapid operation and minimal maintenance requirements.

Maintenance and Testing

Regular maintenance and rigorous testing are paramount for ACBs to function reliably. Nearly 20% of power distribution system failures are attributed to inadequate maintenance. Therefore, a comprehensive maintenance program, including the cleaning of metal spatter in arc chutes and inspection of arcing contacts, is crucial. Testing procedures, encompassing mechanical, thermal, dielectric, and short-circuit tests, ensure that each ACB operates as expected, maintaining the safety and reliability of the electrical system.

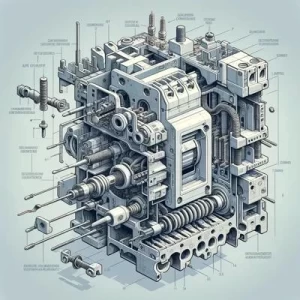

Auxiliary Contacts and Documentation SOPs

Auxiliary contacts play a significant role in the control power for electrical functions within ACBs, such as switching the spring-charging motor and controlling indicator lights. Proper documentation and standard operating procedures (SOPs) are essential for the operation, maintenance, and safety protocols associated with ACBs. These documents serve as a guide for best practices and ensure compliance with safety standards.

Electrical Safety

Electrical safety is a paramount concern when working with ACBs. Safety measures, including Lockout Tagout (LOTO) systems, protect maintenance personnel from electrical hazards. Adhering to established safety protocols and using appropriate safety equipment minimizes the risk of accidents and injuries.

Voltage and Current Ratings

ACBs are versatile, designed for low voltage applications but capable of handling currents ranging from 800A to 6300A or larger. This wide range of operation allows ACBs to be used in various settings, from small-scale industrial applications to large utility networks.

Applications

The application of ACBs extends across a broad spectrum, from UPS systems and generators to mini power stations and distribution boards. Their ability to protect electrical systems from overcurrent and short circuits makes them indispensable in ensuring the stability and efficiency of power distribution.

Air Circuit Breakers are critical for the safety and efficiency of electrical systems, offering protection against overcurrents, short circuits, and electrical faults. Understanding the components and concepts associated with ACBs, such as arc chute, arcing contacts, magnetic blowout type, and air blast circuit breaker, is essential for those working in electrical engineering and maintenance fields. Regular maintenance, adherence to safety protocols, and proper application of ACBs according to their voltage and current ratings ensure the reliability and longevity of electrical systems. The versatility of ACBs in various applications underscores their significance in modern electrical infrastructure, making knowledge of their operation and maintenance a fundamental aspect of electrical engineering.