Legacy Systems: Strategies for Integrating Outdated HVAC Equipment into Modern BAS

Building automation offers powerful tools for streamlining HVAC operations, optimizing efficiency, and improving comfort. However, a significant challenge arises when dealing with legacy systems - older HVAC equipment from various generations that might lack the native compatibility necessary for seamless integration. Confronting this hurdle effectively is key to maximizing the benefits of automation in established buildings.

Understanding the Compatibility Challenge

Proprietary Protocols: Historically, many HVAC manufacturers used closed communication protocols, making their systems reluctant to "talk" to devices or software from other vendors.

Varying Lifecycles: Different components within an HVAC system (chillers, boilers, air handling units, etc.) may have been installed or replaced at different intervals, leading to a mix-and-match environment with no unifying communication standard.

Outdated Control Systems: Older equipment might still rely on basic pneumatic or analog controls, creating a stark contrast with modern digital building automation platforms.

Integration Strategies

The good news is that outdated systems don't have to be a dead-end for automation. Here are several strategies to bridge the compatibility gap:

Gateways and Protocol Translators

These devices act as intermediaries, converting proprietary communication protocols into standard open protocols such as BACnet or Modbus.

They enable the central building automation system (BAS) to understand the "language" of older equipment.

This approach is often suitable for equipment that is still functional but lacks native networking capabilities.

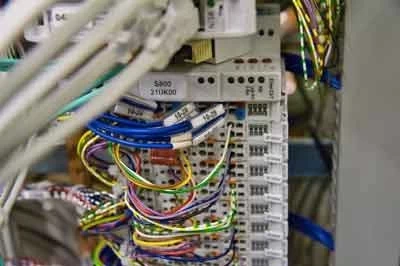

Edge Devices and Distributed Control

Edge devices equipped with input/output (I/O) modules can be installed near legacy equipment to translate analog signals (e.g., temperatures, pressures) into digital data for the BAS.

This approach creates localized control loops, enabling some level of automation and monitoring even for very old systems.

This is helpful when a full-fledged upgrade is cost-prohibitive or if certain pieces of equipment are nearing the end of their lifespan.

Strategic Retrofitting

When budgets permit, consider replacing the most outdated or problematic components with new equipment that has built-in compatibility with the chosen BAS.

A phased approach, targeting the worst compatibility offenders first, can be a less disruptive way of achieving modernization.

This approach aligns well with the natural replacement cycles of HVAC equipment.

Hybrid Automation Approaches

Accept that you might not achieve 100% integration of all legacy systems under a single centralized BAS.

Instead, focus on automating the most critical or energy-intensive equipment, while utilizing standalone controllers or simpler time-based schedules for older secondary systems.

Additional Considerations

Cybersecurity: When integrating legacy equipment, pay extra attention to cybersecurity. Older devices often lack robust security features, potentially creating vulnerabilities in your network. Network segmentation and access control are crucial.

Maintenance Experise: A mixed-technology environment might demand a diverse skillset from your maintenance team or necessitate close cooperation with specialized contractors.

Data Normalization: When integrating data from various generations of equipment, discrepancies in sensor types, units, or naming conventions can arise. The BAS software might need specific configuration to ensure that data is properly interpreted.

The Benefits Outweigh the Obstacles

While integrating legacy HVAC systems into a modern BAS presents challenges, the potential benefits make the endeavor worthwhile:

Centralized Control and Monitoring: Even partial integration affords greater visibility than isolated manual operation of old equipment.

Optimized Efficiency: Automation strategies like scheduling, variable set points, or demand-based control can still yield energy savings for compatible portions of the system.

Improved Fault Detection: The BAS platform can often expose underlying issues within legacy systems through data analysis, preventing major breakdowns.

Data-Driven Upgrades: The insights gained by monitoring legacy equipment through the BAS can guide informed decisions about future retrofits and equipment replacements.

Don't let legacy HVAC systems hold back your building automation initiatives. By thoughtfully considering gateways, edge devices, strategic retrofits, and hybrid approaches, you can build a bridge between the old and the new. This unlocks significant efficiency, comfort, and operational advantages, ultimately extending the lifespan and value of your building's assets.