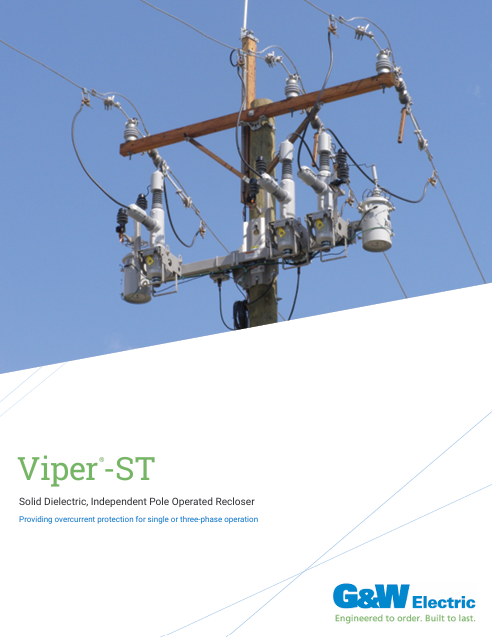

Overcurrent Relays

Electromechanical Relays

Maintenance of Aging Electromechanical Relays

Solid-State Relays (SSR)

SSRs for Renewable Energy Systems

Digital or Numerical Relays

The Rise of Digital Differential Relays

Distance Protection Relays

Mitigating Power Swings on Distance Protection Relays

Motor Protection Relays

Motor Protection Relay Advancements Explained

Protective Relays

Balancing Sensitivity in Ground Fault Relays

In electrical protection systems, ground fault relays play a crucial role in detecting and isolating fault currents that flow to the ground. Achieving the right balance between sensitivity and selectivity in these relays is vital to ensure reliable protection while avoiding unnecessary tripping, a challenge that becomes more pronounced in systems with distributed generation and fluctuating load conditions.

Ground fault relays play a critical role in electrical protection by detecting current leakage to ground. However, achieving optimal performance in modern power systems requires balancing two key characteristics: sensitivity and selectivity. This article explores the importance of this balance and the challenges associated with it, particularly in systems with distributed generation (DG) and varying load conditions.

Sensitivity in Ground Fault Detection

Importance of High Sensitivity

High sensitivity in ground fault relays ensures the detection of low-magnitude fault currents, critical for protecting equipment and maintaining system integrity. This is particularly important in environments with distributed generation sources, where ground faults may not produce high current flows.

Challenges with Over-Sensitivity

However, too much sensitivity can lead to nuisance tripping, where the relay reacts to transient conditions or non-hazardous events as if they were faults. Such unnecessary tripping can lead to unwarranted downtime, affecting...